怎么選擇焊接機(jī)器人的工件附件

來源:http://gouteli.cn/ 發(fā)布時(shí)間:2022-12-17 瀏覽次數(shù):0

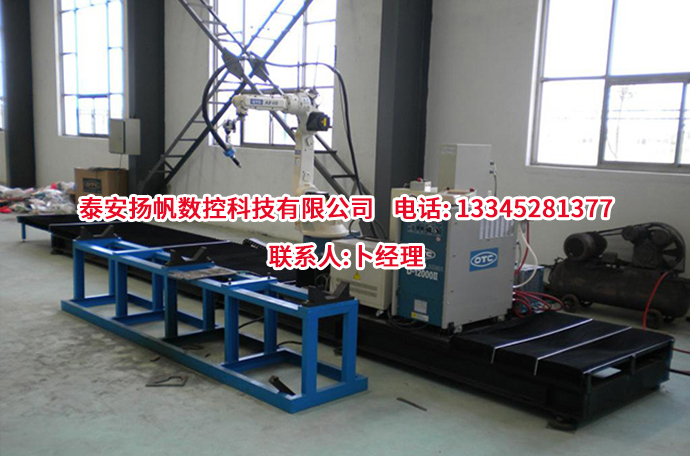

焊接機(jī)器人設(shè)備屬于一條自動(dòng)焊接機(jī)生產(chǎn)線,可以方便地將多個(gè)工作站與工件輸送線連接。盡管它們相互影響,但生產(chǎn)線仍保持單個(gè)工作站的特性。那么,我們應(yīng)怎么選擇焊接機(jī)器人的工件附件呢?下面山東數(shù)控焊接設(shè)備廠家為您進(jìn)行講解。

The welding robot belongs to an automatic welding machine production line, which can easily connect multiple workstations with the workpiece conveying line. Although they affect each other, the production line still maintains the characteristics of a single workstation. So, how should we choose the workpiece accessories of the welding robot? Next, Shandong CNC welding equipment manufacturer will explain to you.

焊接機(jī)器人生產(chǎn)線系統(tǒng)識(shí)別貨盤或工件編號(hào),然后自動(dòng)調(diào)整焊接工件的焊接程序,以便每個(gè)工位無需進(jìn)行任何調(diào)整即可焊接不同的工件。通常有一個(gè)鐵路車,可以自動(dòng)從存儲(chǔ)站中取出固定的工件,并將其發(fā)送到空位置的焊接機(jī)器人的站定位器。也可以從工作站上取下焊件,然后將其發(fā)送到成品出口位置,該位置已被完全使用。

The welding robot production line system first identifies the pallet or workpiece number, and then automatically adjusts the welding procedure of the welding workpiece, so that each station can weld different workpieces without any adjustment. There is usually a railway car that can automatically take fixed workpieces from the storage station and send them to the station locator of the welding robot in the empty position. It is also possible to remove the weldment from the workstation and send it to the finished product exit location, which has been fully used.

整個(gè)焊接機(jī)器人生產(chǎn)線由編程計(jì)算機(jī)控制。將足夠多的零件組裝好并放入存儲(chǔ)站后,任何人或只有很少的人都可以生產(chǎn)它。它適用于多種品種和少量批次的加工。由于機(jī)器人的焊接是重復(fù)性的動(dòng)作,因此只有在附件的定位正確的情況下,焊接機(jī)器人才能發(fā)揮其優(yōu)勢(shì)。

The whole welding robot production line is controlled by a programming computer. After enough parts are assembled and put into the storage station, anyone or only a few people can produce it. It is suitable for processing a variety of varieties and a small number of batches. Because the welding of the robot is a repetitive action, the welding robot can play its advantages only when the attachment is positioned correctly.

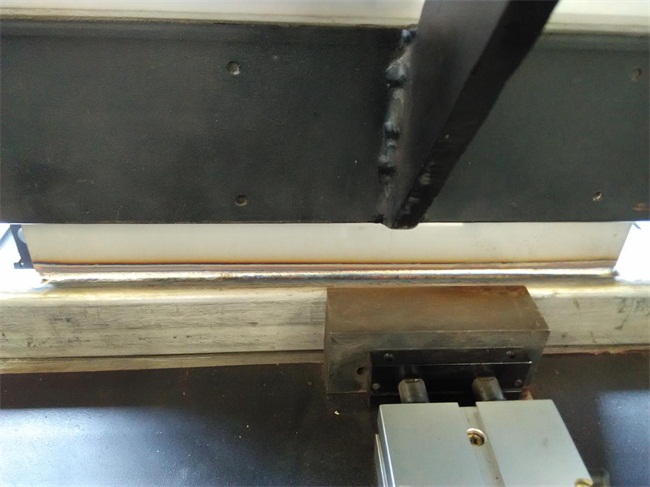

焊接機(jī)器人夾具的結(jié)構(gòu)應(yīng)該簡(jiǎn)單合理,并且易于組裝,調(diào)整,檢查和取材。機(jī)器人焊接包括使用配件固定各個(gè)零件,這些配件可適應(yīng)機(jī)器人的位置,然后使用機(jī)器人焊接將零件焊接在一起,然后將其取下以獲得完整的焊接零件。

The structure of the welding robot fixture should be simple and reasonable, and easy to assemble, adjust, check and take materials. Robot welding includes fixing various parts with accessories that can adapt to the position of the robot, then welding the parts together with robot welding, and then removing them to obtain complete welding parts.

因此,焊接機(jī)器人的焊接工具要能夠順應(yīng)機(jī)器人的位置并保證焊接位置。這就需要機(jī)械夾緊裝置的配合,例如氣動(dòng),液壓或手動(dòng)快速夾緊。您需要從經(jīng)濟(jì)性,適用性和便利性的角度考慮使用哪種夾緊裝置。

Therefore, the welding tools of the welding robot should be able to adapt to the position of the robot and ensure the welding position. This requires the cooperation of mechanical clamping devices, such as pneumatic, hydraulic or manual quick clamping. You need to consider which clamping device to use from the perspective of economy, applicability and convenience.

焊接機(jī)器人生產(chǎn)線上的每個(gè)工位只能使用選定的工件附件和焊接機(jī)器人程序來焊接默認(rèn)工件,所以焊接機(jī)器人的工件附件選擇問題要多重視起來。更多相關(guān)內(nèi)容就來我們網(wǎng)站http://gouteli.cn進(jìn)行咨詢了解吧!

Each station of the welding robot production line can only use the selected workpiece attachment and welding robot program to weld the default workpiece, so more attention should be paid to the selection of workpiece attachment of the welding robot. More relevant content will come to our website http://gouteli.cn Consult and understand!

上一篇:使用焊接專機(jī)前的基本設(shè)備了解

下一篇:預(yù)防數(shù)控焊接設(shè)備問題出現(xiàn)的參考意見